The Swiss industrial ERP for production and ETO management

The most complete and efficient industrial management system on the Swiss market

The reference production management software for Swiss manufacturers for over 30 years

ProConcept is a highly configurable production management ERP that adapts to your processes and to the particularities of your business sector. The software gives you visibility in terms of planning and scheduling to control your production tool and your deadlines.

The suitability of a high-performance ERP to manage ranges and bills of material is inseparable from the success of an ambitious industrial strategy.

You need a complete solution that offers a high level of traceability to satisfy your quality management system ? |

You also want to have precise information on your cost structure, profitability and the accuracy of your cost prices ? |

ProConcept provides you with relevant economic data for the financial and operational management of your industrial activity, which guides your strategic decisions.

Whatever your production methods, make to order, make to stock ,or engineering to order, ProConcept offers you a high-performance, reliable and customizable integrated system. Our ERP solution also ensures the management of projects, frequently encountered in special productions. Project managers can finally conciliate operational excellence and individualised financial monitoring of their projects.

In a few figures

+30

years of experience in industrial management

+17'000

users manage their production with ProConcept

+4'000

users are using ProConcept's customised management

Would you like to know more about the ProConcept Industrie ERP software?

The robust and reliable ERP system adopted by companies looking for recognised business expertise

| ProConcept is an ERP solution for industrial SMEs & ETIs that work on a case-by-case basis or produce in series, and that pay significant attention to industrial efficiency. Thanks to the ProConcept solution, the companies addressed also have the possibility to evolve on a multi-site perimeter in Switzerland and abroad. | Active in the watchmaking, machine-tool, electronics, industrial mechanics or MedTech sectors, your company needs an integrated ERP that can plan productions characterised by a high volume of components where the notion of traceability is important. |

ProConcept offers you a customisable ERP that adapts to your processes.

Take advantage of an industrial ERP that makes you more efficient

Sales management – CRM

Control your marketing campaigns and manage your customer relations !

Purchasing & supplies

Have full control over the requirements and deadlines for your component and subcontracting purchases

S&O and requirements calculation

Manage your Industrial and Commercial Plan, your Production Plan and the calculation of requirements to give depth to your business projections !

Technical data

Manage routings and bills of material to prepare the launch of your production orders with acuity !

Planning and Scheduling

Quickly visualise your shop floor activity and save time with multi-level graphical planning and fine-tuning of your production orders !

Industrial controlling

Control your costs and enhance your production !

Logistics & Supply chain

Manage your stocks and configure your products !

Quality & Traceability

Manage batches and serial numbers with ISO 13485 & FDA compliant software !

Project management

Manage your complex projects with multi-level graphical planning as well as multi-axis budget and financial monitoring !

After Sales Service (AS) Management

Honour your on-site maintenance contracts with your customers and your guarantees with the management of product returns in the workshop !

Finance & Accounting

General & subsidiary accounting / Cost & industrial accounting / Budgetary accounting / Fixed assets / Treasury & cash flow

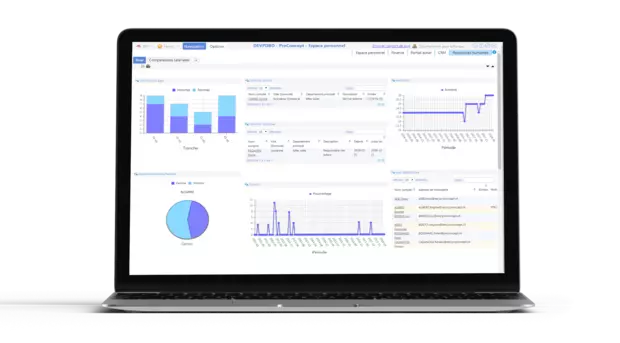

Business Intelligence & Reporting

Build the analytical model that suits you and make your figures speak for themselves !

HR Management

Payroll accounting / Swissdec certification / Personnel administration

Precious materials management

Take advantage of our expertise to accurately manage and trace the use of precious materials in your production process !

Interoperability

Connect all your software and business applications to the ERP !

Multi-currency, Multi-company & Multi-language

ProConcept, le partenaire suisse pour votre projet ERP

1. Swiss editor & integrator for over 30 years, ProConcept is a reliable market player

2. ERP that combines production management in all its forms with the relevance of reliable financial information to increase your economic performance

3. ERP solution favoured by Swiss companies in the watchmaking, MedTech, industrial production and business management sectors

4. Recognised expertise and support in your sector of activity to improve efficiency

5. Flexible ERP that adapts to your processes: comprehensive and customisable modules with strong interactions between functionalities

6. Choice with On Premise or Cloud hosting solution

They trust us

Are you looking for an ERP for finance and human resources ?

ProConcept offers you an integrated and modular ERP software to support the accounting and finance department, as well as HR.