Industrial Production Management

Monitor your company's development effectively

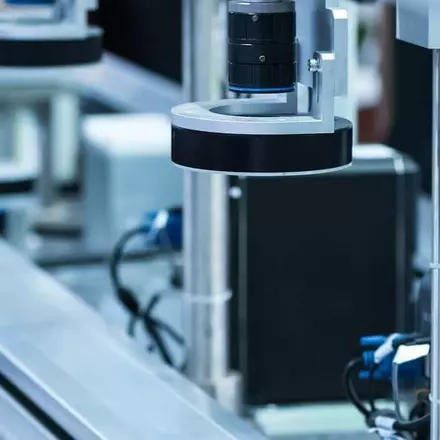

Achieve maximum efficiency using ProConcept ERP's production management tools, helping you to improve the planning, execution, control and monitoring of your shop floor.

Our production management solution delivers a broad range of functionality, from creating product sheets to requirements and production planning (MRP + SIMP), not to mention capacity planning, scheduling and cost control. The ProConcept ERP production management tools deliver powerful yet flexible procedures and parameters. You can manage standard bills of materials and process plans, provisional cost calculations, manufacturing orders, manufacturing monitoring, manufacturing costs, and constraints-based scheduling.

The solution also integrates seamlessly with the other ProConcept ERP modules, including finance and logistics, as well as with a large number of market-standard planning (e.g., Kardex), IT storage, and time management tools.

Sales and Industry MasterPlan (SIMP)

Are your delivery due dates shorter than your production due dates? Let the SIMP anticipate demand from your sales consumption logs and reduce your lead times and costs, by forecasting the supply volume and negotiating an outline contract with your suppliers. The SIMP tools help you supervise production capacity, make coherent budgets according to sales forecasts, and forecast. Forecast monitoring (periodic reviews, comparisons, etc.) is also included.

Requirements calculation (MRP II)

Requirements calculation is the keystone of production management. In today's world, it must include multiple dimensions; technical, economic, and strategic. The questions you ask regarding stock management, logistics, quality, and maintenance will always their answers in the requirements planning tool. Whether the answer is sourcing, making, or subcontracting, the MRP II toolset brings you closer to your business partners.

Scheduling

Operator, tool, purchased materials, varying tooling times, smoothing, graphical load analysis, capacity, and overloading. These are the challenges presented when you are scheduling your production floor. ProConcept ERP can be used to accomplish simple planning all the way to more complex scheduling without constraints. Our robust scheduling functionality shows you the production situation clearly, so that you can then simulate, reschedule, and validate everything in the ERP system before launching your optimized schedule.